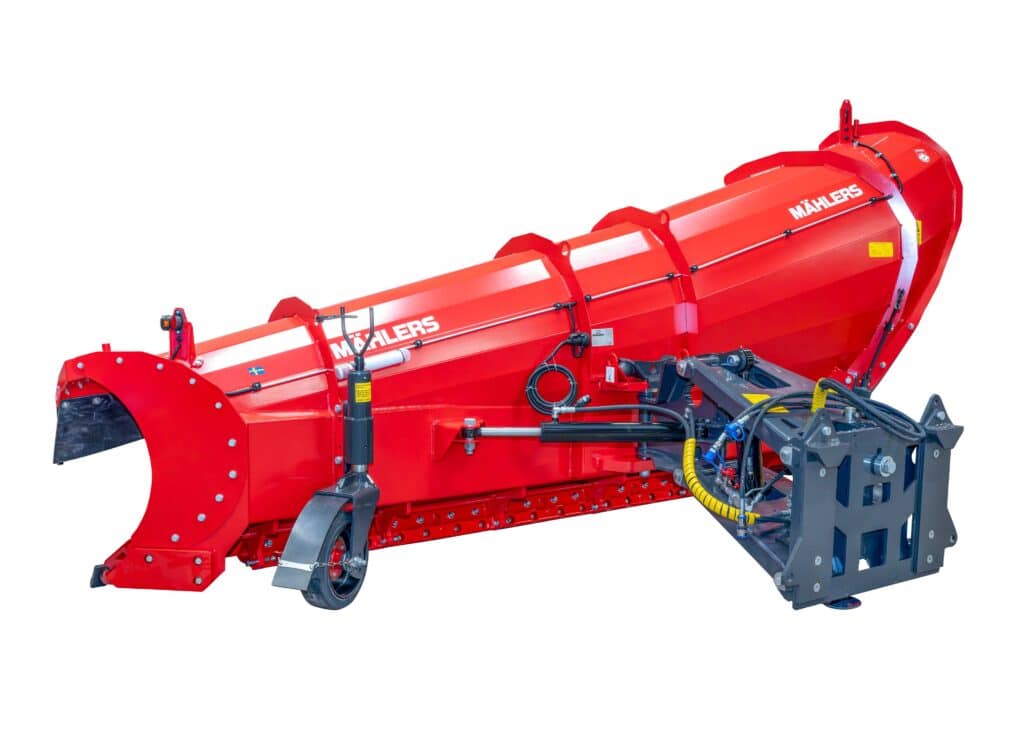

DPF

For really high altitudes

The DPF, aka the Mountain Plough, is the development of the DPH high-throw diagonal plough. Similar in design to the DPH but raised from 1880 to 2100 mm, it also has a unique ejector design that provides the DPF with performance for the most extreme environments.

Like the model it’s based on, the unique design accelerates the snow out of the plough at high velocity. The snow is thrown high and a long way from the road surface. This means the plough leaves a minimal ploughed edge, which is otherwise a common phenomenon when using conventional ploughs. Even at low speeds, plough performance is more than satisfactory.

Unique safety

Like all Mählers products, DPF ploughs are built to be as safe as possible for their immediate surroundings, the plough operator and the vehicle, which is why the DPF has a spring-loaded release system at the base of the plough. The individually released cutter guards prevent damage to the plough and vehicle as well as changes in direction in collisions with protruding obstacles, or if the plough digs in to the road surface.

In addition to this, the parallelogram’s rotation cylinders have built-in shock valves that trigger in the event of a collision with an obstacle. The right side of the plough is clad in low-friction plastic to protect e.g. crash barriers.

Position lights and reflectors come as standard. It is possible to order the plough with reflectors to comply with regulations in the markets concerned.

Together, all of these safety features make DPF ploughs among the safest high-throwing ploughs on the market.

Technical Information

| Type | DPF3700 |

|---|---|

| Operating width 0°(mm): | 3 700 |

| Operating width 30° (mm): | 2 950 |

| Operating width 40° (mm): | 2 820 |

| Min transportation width 43° (mm): | 3 000 |

| Height, right (mm): | 2 100 |

| Height, left (mm): | 890 |

| Rotation (°): | Left ±29 Right ±43 |

| Cutting angle (°): | Linkage 40, Polyurethane 35 |

| Wear bars (pcs): | 4 |

| Wear bar length (mm): | 915 |

| Weight incl fitting (kg): | 1 475 |

DPF advantages

• High throwing height even at low speeds

• Maximum safety with spring-loaded/triggered wear plate holders, minimising the risk of accidents resulting in injuries and damage to property

• Additional safety with shock valves on the parallelogram’s rotation cylinders, which reduce damage in the event of a collision with an obstacle

• Robust design for demanding environments

• Hard-wearing plastic on the right side to protect crash barriers

• Internal screen that prevents cold snow being thrown over the plow

• Built for demanding mountain environment

• Polyurethane wear plates holders follow the road surface and provide calm and quiet running (optional polyurethane insert holder)

Standard equipment

• The DPF is supplied with wear shoes and wear slide runner

• Carbide cutters

• Swedish standard VV-95 or connection to Mählers’ radar hitch

• Hydraulic connection: 4 pcs TEMA-5011

• Edge protectors

Other equipment (optional)

• Wheel assembly

• Lateral displacement 160 mm to the left

• Other attachment points according to applicable standards in e.g. Norway, Finland and Germany

• Polyurethane wear plates holders